The metrics providing the biggest initial impact include utilisation, idling time, fuel consumption, emissions, location, and operating hours. Enabling a single platform view, MachineMax brings a customer’s data together from any source. Providing fast access to the right data to enable in-the-moment and strategic decisions.

The MachineMax solution supports any data source, including their own easy-fit sensors, third-party sensors and OEM telematics.

Amy Law, Marketing Manager, MachineMax said, “With no consolidated view of the fleet, it is often the case that equipment operates sub-optimally, resulting in unnecessary costs, project delays, and a detrimental impact on the environment. An obvious solution is to use live machine data to highlight inefficiencies and underperformance - after all you cannot manage what you cannot measure.”

This notion is supported by Innovation Manager at HS2, Jonathan Kelly, who said: "Collecting plant telematics on a project this size, where we have plant which is not only owned by the joint venture but hired from multiple plant hire companies, required a solution which is plant owner agnostic in its approach, can be attached and removed with ease on site and gives you a holistic view of what’s going on site. This made MachineMax the obvious solution."

MachineMax recently released a case study with infrastructure specialist J. Murphy & Sons Limited (Murphy) who have partnered with MachineMax to consolidate the construction and engineering company’s entire fleet’s data into a single platform, providing them with visibility and the tools to use machine data to drive sustainability, efficiency, and productivity.

The MachineMax platform has allowed Murphy to combine its rental data (from Point of Rental’s Syrinx software, the company’s rental management platform) with fleet telematics from OEM and third-party telematics providers, giving Murphy greater visibility of equipment locations and insight into how its machines are being utilised.

MachineMax is an integral part of Murphy's Digital Transformation Journey, aiming to reduce emissions by 50% over the next five years. The case study focuses on the use of idling data that has helped Murphy to reduce emissions by 10% at HS2 Euston. The case study can be downloaded from the MachineMax website www.MachineMax.com

For more information about MachineMax or to get in touch please email Hello@MachineMax.com

MachineMax is on stand B32 at the show

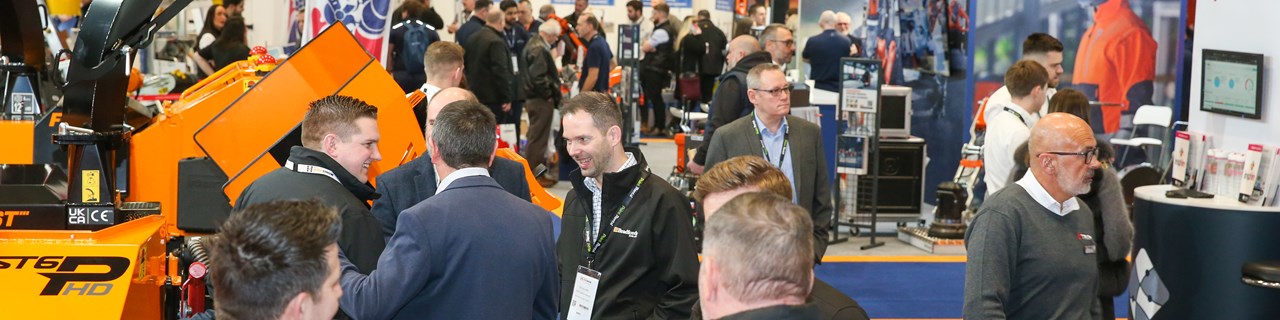

Visit www.executivehireshow.co.uk for more details on the show, the Road Shows and a full exhibitor list. Put the 8th and 9th February 2023 in your diary: the EHS team looks forward to welcoming you back to the Coventry Building Society Arena – the home of hire!

Go to Latest News